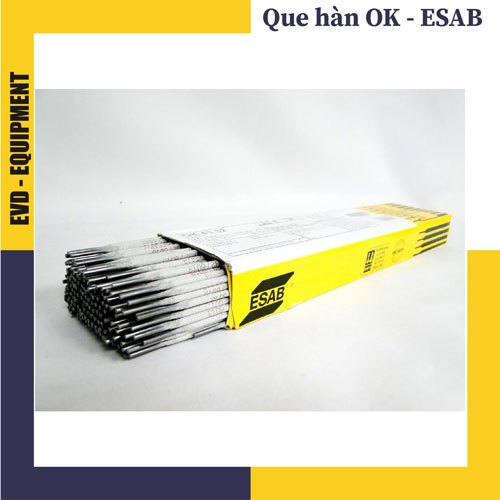

OK 46.00

OK 46.00 is the best, all-round, rutile electrode and it is relatively insensitive to rust or other surface impurities. It deposits smooth weld beads in all positions, including vertical down, and the slag is easy to remove. OK 46.00 is very easy to strike and restrike, making it ideal for short welds, root runs and tacking.

SKU: E6013-2.0

Category: Steel Welding

Typical Tensile Properties

| ISO As welded | ||

| Elongation | Tensile Strength | Yield Strength |

| 28 % | 510 MPa | 400 MPa |

| AWS As welded | ||

| Elongation | Tensile Strength | Yield Strength |

| – | – | – |

Typical Charpy V-Notch Properties

| ISO As welded | |

| Impact Value | Testing Temperature |

| 70 J | 0 °C |

Typical Weld Metal Analysis %

| Mn | C | Si |

| 0.42 % | 0.08 % | 0.30 % |

Deposition Data

| Diameter | Current | Deposition Rate | Fusion time per electrode at 90% I max | kg weld metal/kg electrodes | Number of electrodes/kg weld metal | Voltage |

| 2.0 x 300 mm | 50-70 A | 0.55 kg/h | 38 sec | 0.60 kg | 172 | 25 V |

| 2.5 x 350 mm | 60-100 A | 0.80 kg/h | 50 sec | 0.65 kg | 86 | 22 V |

| 4.0 x 450 mm | 100-200 A | 1.94 kg/h | 76 sec | 0.58 kg | 33 | 23 V |

| 3.0 x 350 mm | 70-140 A | 1.0 kg/h | 46 sec | 0.51 kg | 77 | 32 V |

| 4.0 x 350 mm | 100-200 A | 1.60 kg/h | 65 sec | 0.60 kg | 39 | 22 V |

| 5.0 x 400 mm | 150-290 A | 2.2 kg/h | 71 sec | 0.56 kg | 22 | 30 V |

| 4.0 x 400 mm | 100-200 A | 1.69 kg/h | 64 sec | 0.60 kg | 33 | 26 V |

| 1.6 x 300 mm | 30-60 A | 0.38 kg/h | 36 sec | 0.63 kg | 263 | 26 V |

| 3.2 x 350 mm | 80-150 A | 1.30 kg/h | 57 sec | 0.65 kg | 53 | 22 V |

| 5.0 x 350 mm | 150-290 A | 2.30 kg/h | 87 sec | 0.60 kg | 24 | 24 V |

| 5.0 x 450 mm | 150-290 A | 2.30 kg/h | 114 sec | 0.60 kg | 31 | 24 V |

| 3.2 x 450 mm | 80-150 A | 1.33 kg/h | 63 sec | 0.64 kg | 43 | 22 V |

| Approvals: | ABS, 2, PL,SF, BV, 2, PL,SF, CE, EN 13479, SB,SF,SA,PL,HG, DB, 10.039.05, HG,PL,SA,SF, DNV, 2, PL,SF, GL, 2, PL,SF, LR, 2, PL,SF, RS, 2, HG,SA, VdTÜV, 00623, HG,PL,SA,SF, BKI, 2, PL, ClassNK, KMW2, PL, NAKS/HAKC, 2.5, 3.0, 4.0, 5.0 mm, HG, SA, NAKS/HAKC, 3.0-4.0 mm, PN,MI, NAKS/HAKC, 3.2-4.0 mm, SF, RRR, 2 |

| Classifications: | SFA/AWS A5.1, qUE, EN ISO 2560-A, E 38 0 RC 11, GOST 9467-75, E46, GOST R ISO 2560-A, E 38 0 RC 11 |

Approvals are based on factory location. Please contact ESAB for more information.

| Alloy Type: | Carbon Manganese |

| Coating Type: | IMPERIAL_Rutile-cellulosic covering |

| Welding Current: | AC, DC+- |