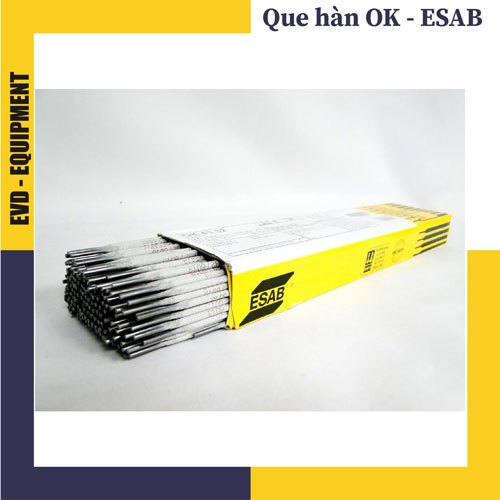

ESAB 4301

An easy to use AC and DC electrode. Suitable for welding mild steels and pressure vessel steels having a nominal tensile strength not exceeding 440 N/mm2. The electrode can be used for welding of structural steels of heavy section about 25 mm in thickness.